When assessing a post-collision AC system, examine external damage like dents and leaks in hoses and seals. A qualified collision repair shop ensures all components are safe and functional. During repair, focus on compressor and condenser coils for deformation or cracks, replacing damaged parts. Verify refrigerant levels and check for leaks using specialized tools to maintain efficiency and safety, addressing leaks promptly to prevent environmental harm.

Post-collision AC systems require meticulous inspection for safe and efficient operation. This comprehensive checklist guides collision repair professionals through the critical steps of assessing external damage, inspecting key components like compressors and condenser coils, and verifying refrigerant levels and leaks. By adhering to these protocols, technicians ensure that repaired AC systems not only function optimally but also maintain safety standards, providing passengers with a comfortable and hazard-free driving environment.

- Assessing External Damage to AC Unit

- Inspecting Compressor and Condenser Coils

- Verifying Refrigerant Levels and Leaks

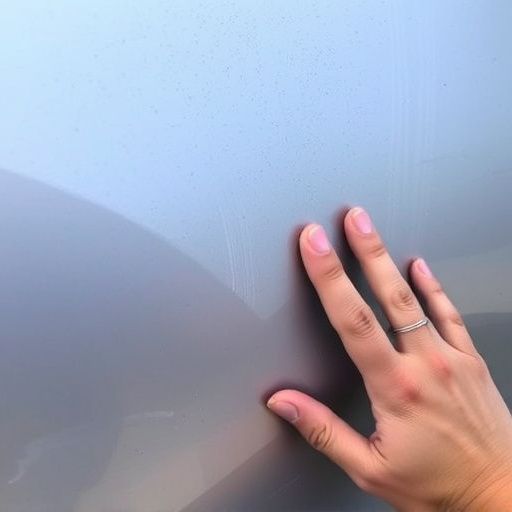

Assessing External Damage to AC Unit

When assessing a post-collision AC system, the first step involves meticulously examining the external damage to the unit. This includes checking for any visible signs of impact, such as dents, scratches, or cracks in the casing, which could indicate structural compromise. It’s crucial to also look for leaks in hoses and seals, as these can not only affect the performance of the AC system but also lead to further damage if left unattended.

Additionally, inspect the evaporator coils for any obstruction or damage. Debris like dirt, dust, or even small branches can obstruct airflow, leading to inefficient cooling. Car paint repair might be necessary if the external damage is significant, especially in cases where the unit has been pushed out of alignment or experiences visible cosmetic damage. Remember, a thorough assessment by a qualified collision repair shop is essential to ensure that every component of the AC system is safe and functional before proceeding with any automotive repair.

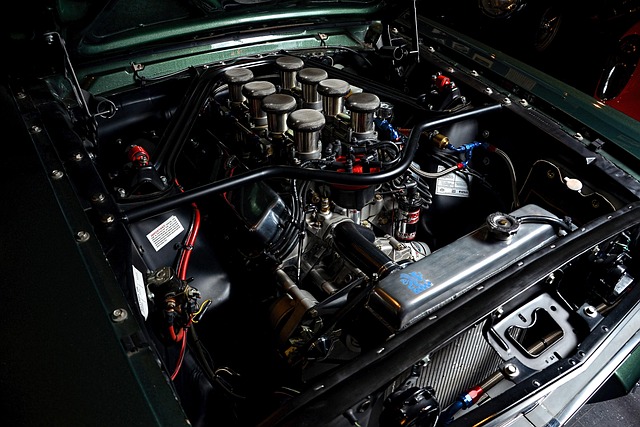

Inspecting Compressor and Condenser Coils

During a full inspection of an AC system after a collision, paying close attention to the compressor and condenser coils is paramount in the auto repair process. These components are crucial for the efficient functioning of the AC system, and any damage can significantly impact cooling performance or even render the entire unit useless. Look for visible signs of deformation, corrosion, or cracks on the coils. It’s important to note that a meticulous inspection should also include checking for leaks, as even tiny ones could indicate a compromised seal.

In automotive restoration, ensuring these parts are in pristine condition is key. The process may involve replacing damaged or worn-out coils with new ones, a task that requires skilled technicians equipped with the latest tools. While scratch repair might be relevant for cosmetic considerations, prioritizing functional repairs first and foremost guarantees the restored AC system’s longevity and effectiveness, especially in extreme weather conditions.

Verifying Refrigerant Levels and Leaks

After a collision, one of the critical steps in AC system maintenance is verifying refrigerant levels and checking for leaks. This process ensures the efficiency and safety of the air conditioning system post-repair. Technicians should begin by inspecting the system for any visible signs of damage, such as dents or cracks, especially around the compressor, evaporator coils, and refrigerant lines. Any observed damage must be addressed during the collision repair process to prevent further complications.

Using specialized tools, a comprehensive inspection of refrigerant levels is essential. This involves checking the low-side and high-side pressures to ensure they align with the manufacturer’s specifications. A slight variation is normal, but significant deviations could indicate a leak or system imbalance. Leaks can be detected through visual inspections, scent (refrigerant has a distinct odor), or using ultrasonic or electronic leak detectors. Promptly addressing leaks is crucial in collision repair shops to prevent environmental harm and ensure the AC system functions optimally after scratch repair.

When conducting a full inspection checklist for a post-collision AC system, meticulous attention to detail is crucial. By assessing external damage, inspecting compressor coils, and verifying refrigerant levels, collision repair professionals can ensure that the AC system not only functions optimally but also meets safety standards. This comprehensive approach to collision repair guarantees that vehicle owners receive a reliable and efficient cooling system, enhancing their driving experience. For effective AC system collision repair, adhering to these meticulous steps is essential.